There can be countless times when you would be gaming on your computer, only to realize that it is getting extremely hot and everything is starting to lag. This will typically happen when your CPU is overheating, and it can cause the entire system to lag down, and therefore it can cause your computer to slow down by a lot.

Over time, not only can that be detrimental to your computer’s health, as it can cause the battery to get more weakened, but it can also cause your computer’s performance to deteriorate too, as a cooler CPU is the key to running your computer smoothly. If it is not working properly and instead it is overheating, that means that your computer will find itself being stuck in issues too.

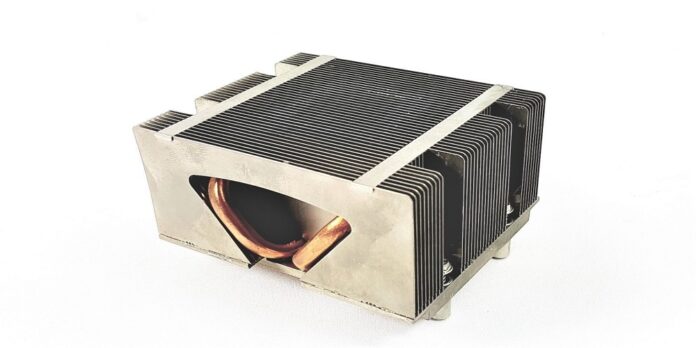

Therefore, to counteract these major issues, people have started to look for heat sink manufacturers that have been detrimental in cooling down a CPU. the way they work is by channeling cooler liquid that will dissipate the heat from your CPU to another corner. It will cause your CPU to work more smoothly in the end.

Now, you might be wondering how many kinds of heat sinks there might be, how all of them are manufactured, and what different techniques might be there for them to be manufactured. We will cover all of them. Without further ado, let’s get started!

Extrusion

One of the biggest and most cost-effective ways of heat sink production is known as extrusion. Not only is it one of the most cost-friendly ways, but it also takes the least amount of time to manufacture. It is made with plate fins, it is done through the process of extrusion, and it can help with the cheap manufacturer, and therefore is one of the most highly used production methods.

Cold forging

Another important way that heat sinks are desired to be made that are consumer-friendly and extremely important is known as cold forging. It is an extremely precise method that requires a lot of intricate detailing to be done. It is made to make round pin heat sinks and oval pin heat sinks, allowing them to be more compact and user-friendly overall; it is very desired.

Stamping

Another way of making heat sinks that is typically less known but still just as effective is stamping. Not only is it an excellent way, but it is far more useful as it requires lesser use of materials, but it ends up giving a bigger outcome; therefore, it is lesser-known. However, it is more expensive. Stamping is done by getting heat pipes that will travel through the fins that can easily dissipate that heat that the CPU has been collecting over time and get rid of it.

Skiving

Last but not least, we will cover skiving, which is a technique that is not used anymore due to the extremely expensive costs. However, it is still very impressive when making heat sinks.

Ending notes

All in all, these are some ways that a heat sink is made, so your CPU can benefit from it and work properly.